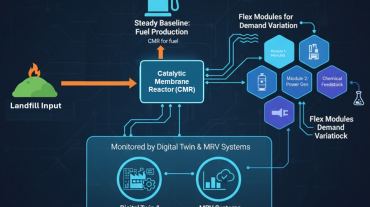

CMR is McAlpha’s flagship advanced reactor platform geared towards decarbonization, enabling high-efficiency, low-carbon fuel synthesis through simultaneous reaction and separation.

Core Capabilities Low-Carbon Hydrogen Production: Advanced hydrogen generation using Catalytic Membrane Reactor (CMR) technology, enabling high-yield production with significantly reduced carbon emissions. Ideal for industrial, refining, and clean fuel applications. High-Efficiency Ammonia Synthesis: Decentralized ammonia production through integrated hydrogen generation and nitrogen separation. The system delivers cost-effective, low-emission ammonia for fertilizer, energy, and chemical markets. Dual-CMR Synthetic Crude Production: Conversion of organic waste and biogenic feedstocks into syngas and synthetic crude via a dual-reactor CMR system that combines reforming and catalytic upgrading, supporting circular fuel pathways and methane abatement. Integrated CO₂ Utilization: Built-in capability to convert CO₂ into value-added fuels, chemicals, or industrial feedstocks, supporting carbon circularity and alignment with global emissions reduction targets.

Key Advantages

- 90%+ higher clean fuel yield vs. conventional systems

- Integrated reaction + separation reduces cost and complexity

- Modular design suitable for remote, industrial, or off-grid deployment

- Significant reduction in lifecycle greenhouse-gas emissions